Faccenda Foods to implement SonoSteam technology

Faccenda Foods to implement SonoSteam technology after successful trial

- SonoSteam technology to move to continuous running

- Over 80% reduction in Campylobacter proven during in-line trials

- £1m investment in SonoSteam is one element of a comprehensive Campylobacter plan

Brackley, UK – Faccenda Foods, one of the UK’s leading food companies, has confirmed that its extensive in-line trials with SonoSteam technology have been successful and the next phase of its implementation, continuous running, will start in June 2015. Results from the SonoSteam trials have shown more than an 80% reduction in Campylobacter on the neck and breast skin of fresh, whole chickens; measured at the point in time when the consumer would typically purchase and cook the chicken.

Faccenda Foods is the first UK poultry producer to invest in SonoSteam technology and conduct comprehensive, full scale in-line trials. The £1m commitment to the technology is just one element of a comprehensive plan that touches every link in the Faccenda supply chain. The SonoSteam equipment was installed and commissioned in December 2014, and trials have been completed every week from January to May 2015 enabling performance to be refined. The excellent results from this intensive trialling process means Faccenda are now ready to move to the next phase of fully integrated continuous running, before the end of June.

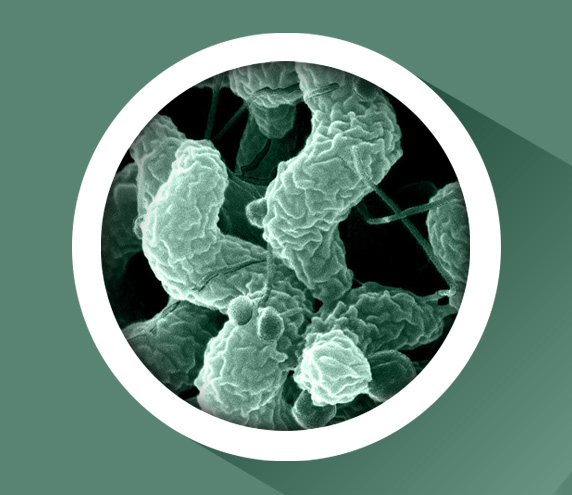

SonoSteam kills Campylobacter and other micro-organisms on the skin of chickens through the simultaneous application of both steam and ultrasound, a process that takes just 1.5 seconds. Sonosteam is so effective because the process is consistently applied to every single bird. As well as being extremely effective, using only steam and ultrasound limits the environmental impact of the advanced technology.

Faccenda Foods Managing Director Andy Dawkins said: “While the industry is agreed that there is no silver bullet to solve the Campylobacter problem, we are very excited by results from our in-line trials which proves that SonoSteam will work in the real world. There is still a great deal of work for us all to do but, as part of our wider Campylobacter Action plan, I’m in no doubt that SonoSteam will help us significantly reduce levels of Campylobacter and improve food safety for consumers.”

SonoSteam Vice President Niels Krebs said: “It’s important not to underestimate just how challenging it was to successfully conduct a technology trial in-line. The investment so far has been very significant but the results show it has been worth it. Faccenda Foods now has a proven, intervention which is ready to operate on a continuous basis and which can be applied to every chicken on the line. Importantly, the in-line trials have proven that SonoSteam can be a key technology in helping the poultry industry significantly reduce the risk from Campylobacter.”

SonoSteam is another first for Faccenda Foods, having previously led the industry with its award-winning Roast in the Bag products, developed in partnership with Asda. The innovative packaging means consumers can put the product straight in the oven without having to handle any raw chicken, taking food safety in the kitchen to another level.

The Food Standards Agency has been a keen supporter of both of these innovative approaches to tackle Campylobacter which demonstrate Faccenda’s multimillion pound commitment to tackling the problem at all points of the supply chain to achieve the 2015 Campylobacter Reduction Target.